Restoration: PHASE 3

DETAILS — LANTERN ROOM

TIMING: June 2017 to July 2021

Note: Project work was halted for over a year during this period, due to Covid-10 pandemic restrictions.

FUNDING FOR THIS PHASE INCLUDED:

- Donations from SPLPS membes/supporters

- Westaway Charitable Foundation — donation

- Community Gaming Capital Grant (Province of British Columbia)

To view the comprehensive, Final Restoration Report (Phases 1 to 3), please click here.

Lantern Room Restoration — Corrosion

Rationale: The lantern room, which traditionally houses the lens for the lighthouse beacon, is the focal point of the Lighthouse. The condition assessment identified serious corrosion, mostly due to weather and to ingress of moisture within the lantern room. While the main wall plates were in acceptable condition, the window frames, door, exterior rails and ladders and parts of the roof appeared to be in much poorer condition and in need of more detailed analysis. Potentially, some of these elements would need to be rebuilt or even replaced. Without this work, the integrity of the entire structure would be compromised, and would be unsafe for the Society to maintain.

Heritage context: As this is, perhaps, the most sensitive and noticeable component of the heritage character of the Lighthouse, (and one of the primary “character defining elements” of the Statement of Significance) great care had to be taken to ensure that the restoration plans maintained the heritage values and character of the lantern room.

CORROSION REMOVAL — EXTERIOR: Although most of the exterior corrosion had been removed during the previous phase, remaining work on the copper roof dome was completed. Also, detailed work on the external ladders, rails and catwalk was completed.

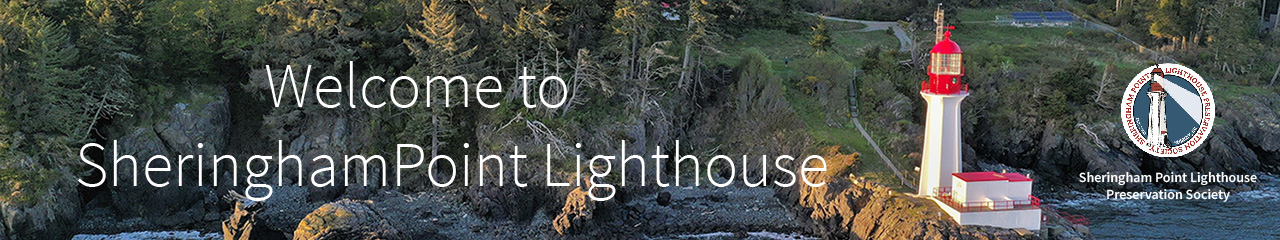

CORROSION REMOVAL — INTERIOR: The interior walls, stairs and catwalk were only minimally corroded, and were addressed in areas as required. The support struts, however, were more seriously corroded and great care was taken to ensure they were cleaned comprehensively, as they are the key component of the structural integrity of the lantern room. (Pole jacks were used to support the roof during this work). Also, the supporting beams on the underside of the roof dome had significant corrosion due to roof leaks, and were cleaned thoroughly.

CORROSION REMOVAL — DOOR: The door to the exterior of the lantern room was severely corroded, and this prevented the door from closing properly (thus adding further to the corrosion. As much corrosion was removed as possible, but it was determined that the inside panel of the door was not salvageable. And so, the door was removed and taken to the shop (Foggy Mountain Forge, of Shirley, BC) where the interior panel was removed and a new panel welded in place.

Lantern Room Restoration — Windows

RATIONALE AND HERITAGE CONTEXT: The lantern room contains 36 curved window panes, approximately 1-metre square. All but two of these windows were broken or missing. During the years since the lighthouse was de-staffed, many of the windows had been used as “target practice”, and were shattered or contained bullet holes. Others were cracked, sometimes severely, and several had pieces of glass missing. A few glass panes were missing entirely and had been replaced, at some time in the past, with plexiglass which had since yellowed. As a key character-defining element, it would have been preferable to retain as much original glass as possible. However, due to the extent of damage, only two panes were salvageable – most of the panes fell apart upon removal. It was determined that new, replacement panes would be required throughout.

ACTIONS TAKEN: Using one of the existing panes as a template, new panes were manufactured (and bent) at the Gilchrist Glass Bending Ltd. shop in Mill Bay. The new panes were installed by Sooke Glass Ltd. During installation it was determined that there had been minor variations in the heights of the original panes (no more than 1/4 inch) and, because all the new panes were identical in size, additional horizontal spacers would be required to hold the new windows more tightly in place. These spacers were manufactured at Foggy Mountain Forge.

Lantern Room Restoration — Painting

RATIONALE AND HERITAGE CONTEXT: It was not known exactly when the lantern room – either the exterior or the interior were last painted, but it was at least thirty years ago. Both the exterior and interior paint was excessively worn and, with the amount of corrosion was in poor shape. In addition, the corrosion removal process (grinding), particularly on the exterior, also removed the paint covering. Accordingly, both the exterior and interior of the lantern room required full painting. As the appearance of the lighthouse, with its “signature” red and white colours, is a character-defining element, care was taken to use the colour and paint specifications required by the Canadian Coast Guard for their own lighthouses.

ACTIONS TAKEN: Island Applicators Ltd., who did all of the previous corrosion removal and preparatory work, have considerable experience working with lighthouses (in fact they did the previous restoration of Sheringham Point Lighthouse in the 1980s). As such, they were well-versed in the requirements and colours required for the painting. The exterior of the lantern room received three coats – a primer epoxy sealer, a base coat (also epoxy), and a top coat (polyurethane). The dome received an additional top coat, as well as additional epoxy sealer along the seams (to prevent further leaks). The colour used for the exterior was CCG Flame Red. On the interior, two or three coats (depending on location) were applied over the existing paint. The colours used were CCG Signal White for the walls and roof, and CCG Deck Grey for the floor and catwalk.

Lantern Room Restoration — Weather Vane

RATIONALE & HERITAGE CONTEXT: The weather vane, situated at the top of the lighthouse dome, was excessively corroded, such that it was “frozen” in place and no longer turned with the wind or functioned as a weather vane. While it was no longer connected to the Sheringham Point weather station, it was still an iconic component of the Lighthouse and a character-defining element. Accordingly, it was decided to restore the weather vane to the extent possible.

ACTIONS TAKEN: The weather vane was removed from the dome, and taken into the shop (at Foggy Mountain Forge) for examination. It was carefully dismantled and each of the components cleaned, lathed as necessary and zinc-coated to prevent further corrosion. Replacement brass bolts were necessary with some components. The mounting rings, which connect the weather vane to the dome were corroded beyond repair, and replacement rings were fabricated.

Once returned to the lighthouse site, the weather vane was painted to match the exterior of the dome and put back into place. It now turned freely and once again indicated the wind direction.

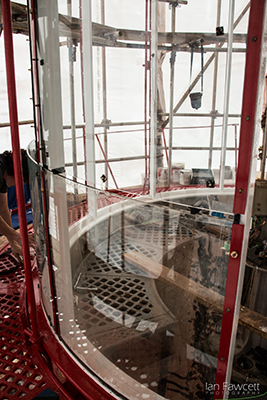

Lantern Room Restoration — Vents

RATIONALE AND HERITAGE CONTEXT: There are twenty small round vents in the lantern room walls. These vents are designed to be opened or closed as necessary to help regulate the significant temperature fluctuations in the lantern room. However, most of these vents were no longer functional due to many layers of paint buildup over the years, which jammed the open/close mechanism in its place – some open and some closed. As a character-defining element, it is important that the lantern room be maintained in as optimal a condition as possible, and the temperature regulation from the vents goes a long way to helping this. Accordingly, it was deemed necessary to fully clean the vents and make them operable again.

ACTIONS TAKEN: Each of the vents was removed from the wall, and taken to the foundry (Smith Bros. Foundry, Victoria) where they could be thoroughly cleaned with sand-blasting, and all the paint residue removed. Although they had been previously painted white, it was decided not to repaint them, as it was felt this hindered their proper functioning, and instead, to leave them as bare brass. During cleaning, it was determined that some of the central screw-handles, which turn the vent blades, were no longer functional due to corrosion, and so were replicated (Smith Bros. Foundry, Victoria).