THE FOGHORN

There is no sound more iconic in coastal areas, nor one that can stir up emotions on a foggy, dark night more so than the low-pitched, soul-stirring drone of a foghorn. While the light is the primary signal for lighthouses, on foggy days or nights, or when visibility is limited by other weather conditions, a foghorn is also used to protect and provide direction for mariners.

A Canadian Invention

In 1853, Robert Foulis – a Scotsman and civil engineer who had emigrated to Saint John, New Brunswick – invented the first automated steam powered foghorn. It was installed at Partridge Island in the Bay of Fundy in 1859. This foghorn design grew in popularity and was soon installed in many lighthouses worldwide.

While a significant improvement over previous options, the steam powered foghorn also had its drawbacks. The boilers used to create the steam power required keepers to shovel a ton of coal (or 2/3 of a cord of wood) for every ten hours of operation. And large amounts of smoke and soot both interfered with the light operations and had to be constantly cleaned off the lights.

Then, In 1903, John Pell Northey of Toronto patented the Diaphone foghorn. Northey adapted the diaphone technology used in pipe organs and combined it with the recently invented diesel engine powered air compressor. Northey’s design resulted in a more effective operation as well as a more powerful signal that could be heard over greater distances, and it was widely adopted.

Sheringham Point Foghorn

In about 1924, a Canadian Pacific passenger liner was passing Sheringham Point in dense fog. The vessel was slightly off course and came perilously close to striking the reef just off the point. Following this “near miss”, it was decided to install a foghorn at Sheringham Point Lighthouse.

The Diaphone Foghorn

In 1925, a diaphone foghorn was installed at Sheringham Point. To house the foghorn and its associated equipment, a new, wood-frame “fog-alarm” building was constructed at the base of the tower.

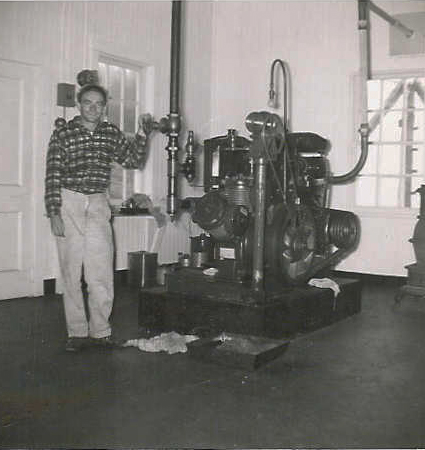

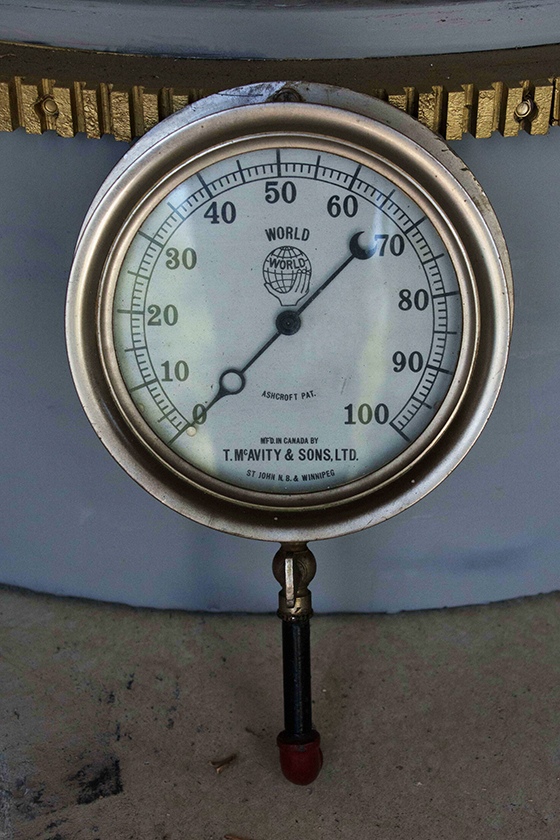

The components of the foghorn included a Lister diesel engine, an Ingersoll-Rand air compressor, a compressor tank and the foghorn “trumpet”, or “bell”. There were also switching mechanisms and pressure gauges attached to the equipment.

When fog was detected in the area, the lightkeeper would turn on the foghorn and start up the diesel engine. This was connected by drive belts around the flywheel at the front of the air compressor, which would then activate the compressor. The compressor was connected by metal pipes to the large compressor tank, which stored the compressed air.

When adequate pressure was attained in the tank (measured by the pressure gauge), a switch would open a valve allowing a blast of compressed air to move through the foghorn and produce a very loud signal that could be heard (depending on weather conditions) for several kilometers. The duration of the blast was governed by a timer connected to a mercury switch — it would produce a signal (a higher pitched note, followed by a much lower pitched note) for 6 seconds, followed by an interval of 54 seconds (this was Sheringham Point’s “foghorn signature”.

Repatriation and Restoration

Eventually, diaphone foghorns began to be replaced with newer (and cheaper) technology. The engines and compressed air were replaced with batteries and electronic horns. At Sheringham Point, the diaphone foghorn was removed and replaced with two AGA 2KW foghorns, along with an AGA FDBV 100 fog detector.

The original equipment was, in turn, donated to the Sooke Museum where it was displayed for a number of years. In 2019, it was transferred to the Sheringham Point Lighthouse Preservation Society, on a permanent loan, and in 2022 it was brought back to the site and displayed at the new visitors’ centre.